It is no coincidence that this modern kitchen mixer is made of brass - it is a material that ensures its maximum durability and longevity. For additional protection, the brass has been coated with several layers of protective chrome, which makes the kitchen tap an element of kitchen equipment with special technical and visual qualities.

Kitchen faucet with Black flexible hose Kitchen taps with Pull Out Spray hot and cold Kitchen sink faucet mixer tap

|

Product Name

|

Kitchen faucet

|

Material

|

Brass

|

|

Brand name

|

SINERMEI

|

Flow rate

|

20L/mins

|

|

Application

|

House

|

Surface Finishing & Treatment

|

Chrome

|

|

OEM&ODM

|

Accept

|

Modes of packing

|

12pcs Packed in 1 cartons

|

Detailed Images

The effective stream of water makes using the kitchen faucet pleasant and comfortable.

The handset is equipped with a switch for selecting two stream functions. In addition, it is an easy-to-clean device, which saves

time spent on cleaning.

time spent on cleaning.

A standing faucet with a mousseur is characterized by a slim shape that will delight every lover of practical and elegant things.

Height:455mm

Spout height:175mm

You can choose different lever according to your preferences and usage habits to ensure your personalized customization needs.

The comfortable and stylish lever makes the daily use of this faucet a real pleasure for every household member.

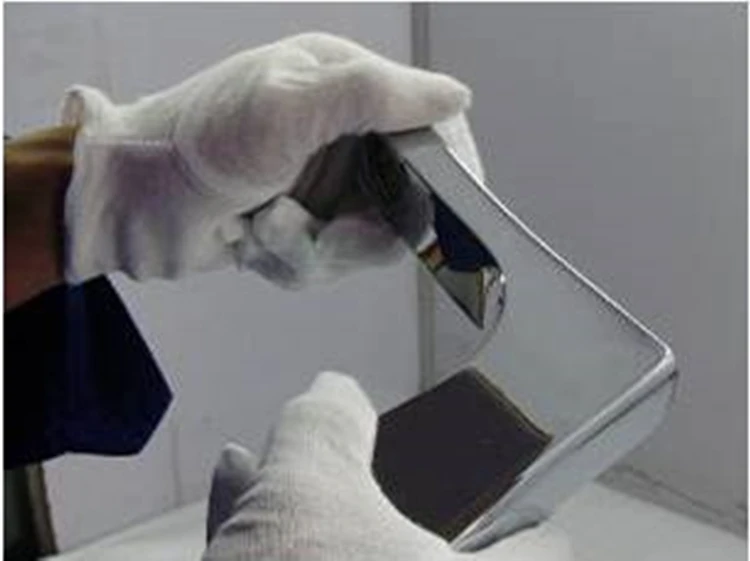

Seven-layer process surface

Up to seven layers of plating process

Quality and manufacturing process can be seen with the naked eye

High temperature resistant

Explosion-proof

Anti-freeze crack

EPDM inner tube Anti-high pressure

Manufacturing Technology and Quality Control

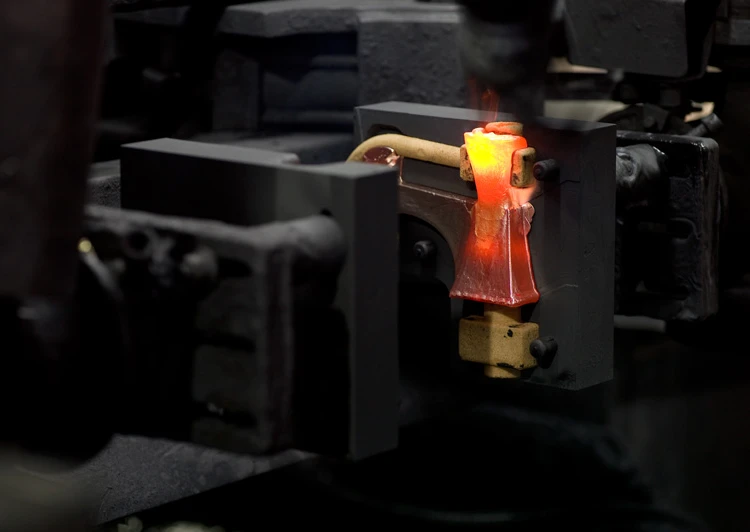

Owned Foundry

We have our own foundry, rich casting experience and high finished product rate. Guarantee the timely supply of products.We have traditional sand casting and high quality gravity casting to meet your different product needs.

Select high quality brass material

We use instrument grade (extra A grade) brass ingots, national standard GB 59-1, with lead content ≤ 1.2%. After polishing, no impurities, sand holes, cracks, waves, etc. are allowed. The quality requirements are extremely stringent, exceeding national standards and fully conforming to international standards.

Gravity casting technology

Adopting advanced gravity casting technology, the faucet shell is formed by the international top Italian IMR gravity casting and sand core molding equipment, which produces products with tight structure, dense crystallization, uniform thickness and smooth surface.

Automatic machining center

Using the world's most advanced CNC (automatic machining center), multi-step processing in one time, to ensure the ultra-high precision of the processing size and the finish of the processing surface, to ensure the long-term sealing performance of the product.

Automatic plating line

We have fully automatic plating line, scientific and refined nickel plating process, multi-layer nickel plating to ensure the excellent quality of product appearance.

Scientific assembly process

We have a group of assembly workers with more than 10 years of experience. The scientific level of manual assembly has been greatly improved to ensure the high efficiency of assembly and the qualified rate of products.

Standard Warehouse

We have over 2000 square meters of standardized warehouses. It is conducive to the storage of raw materials, semi-finished or finished products.

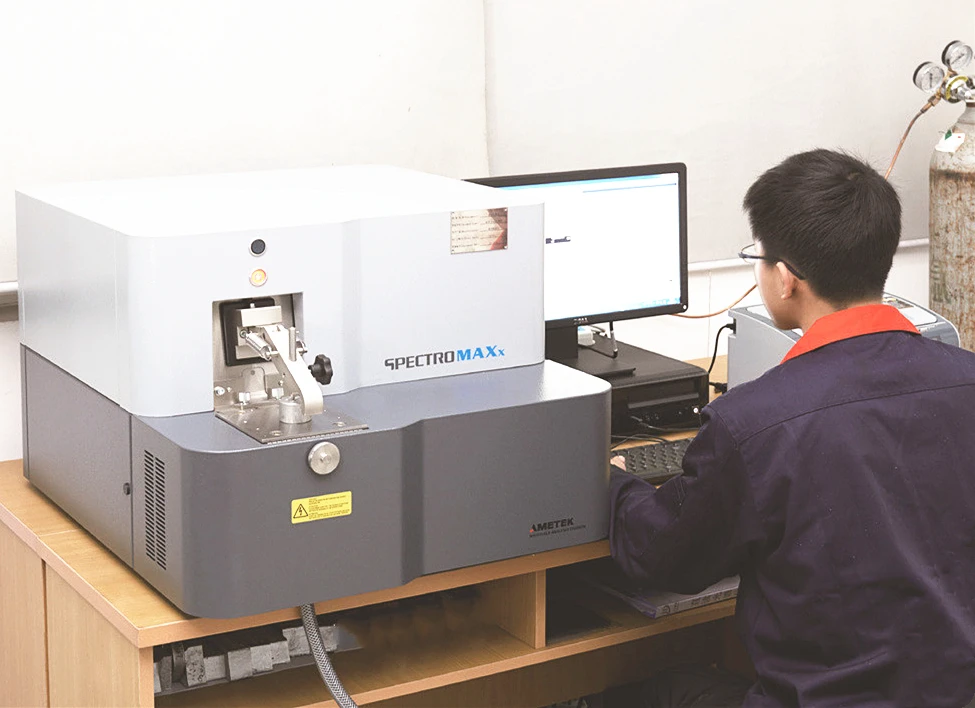

We use the German SPECTROLAB spectrometer to test the composition of each furnace copper water, to ensure that the material of the product out of the furnace qualified, and will keep the test sample for 3-12 months for quality tracking.

For products, we conduct airtightness testing and water testing experiments to ensure that the products are airtight and do not leak.

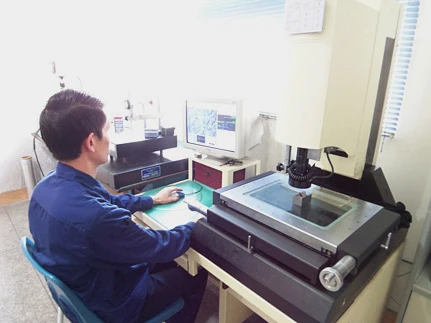

We use the quadratic measuring machine to check the hole center distance, position, profile, slope, concentricity, and cylindricity of our products. We guarantee that the quality of each product is up to standard.

We conduct 48-hour salt spray testing on copper and stainless steel products to ensure that the products are not easily rusted, corrosion resistant and durable.

For products with organic performance requirements, we conduct hardness tests to ensure quality requirements.

We use metallographic microscopes to identify and analyze copper and stainless steel materials, conduct raw material inspections, and ensure the quality of our castings.

100% inspection of the key dimensions of the products, appearance of all castings before shipment.

For the surface of polished finished products, 100% fine inspection is passed.

We require all suppliers to provide warranties and certificates of conformity for the quality of materials, and we also test the materials incoming.